Your cart is currently empty!

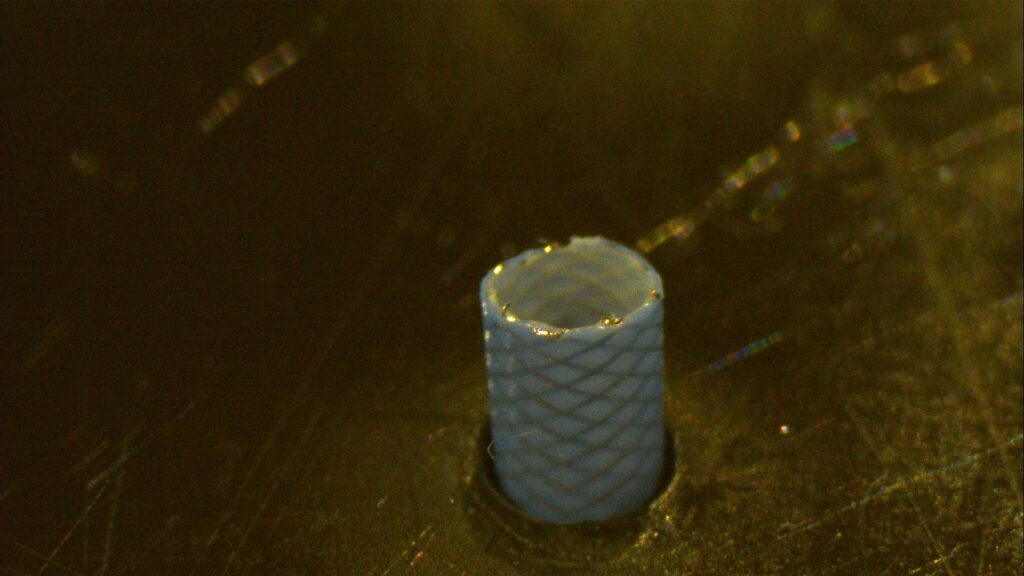

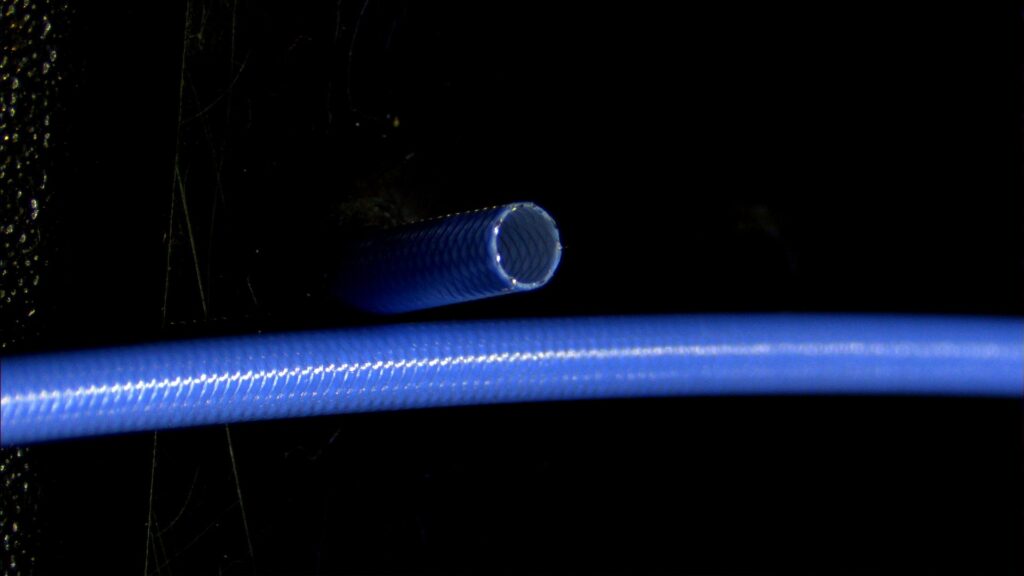

Braid Reinforced Tubing

Renegade’s Continuous Braid Reinforced Tubing

Renegade proudly offers continuously braid reinforced tubing, crafted using our in-house 16 or 32 carrier braiders.

What is Continuous Braid Reinforced Tubing? This tubing is primarily processed through extrusion, providing an economical solution for typical shafts or delivery catheters.

Benefits:

Customizable Layers: Our proprietary process allows for unique materials in each layer, whether different durometers within the Pebax® family or entirely different polymers.

No Heat Shrink Required: Our braided shafts eliminate the need for heat shrink, reducing the risk of unnoticed nicks from razor blades during removal.

Minimal Tack Time: Our process minimizes tack time, lowering contamination risks and further reducing costs.

Capabilities

- 16 carrier

- 32 carrier

- Variable pic braiding

- Segment braiding

- Diameters <0.200″

- Unique material per layer

Why Choose Braid Reinforced Tubing? Braid reinforced tubing offers numerous benefits, including:

- Improved Torque Control

- Enhanced Pressure Resistance

- Greater Flexibility

Experience the advantages of braid reinforced tubing with Renegade’s innovative solutions!